Installation

and dimension

Servo

motor

Servomotor

can be installed either horizontally or vertically. However, if the

servomotor is installed with incorrect mechanical fittings, the servo

motor’s lifetime will be greatly shortened and unexpected

accidents will occur.

Please

make installation according to the instructions as below:

Precaution:

There’s

some antirust agent on the edge of the motor shaft to prevent it from

rusting during storage. Please wipe off the agent thoroughly by using

a cloth dipped with diluting agent or thinner before installing the

motor.

NOTE:

The diluting agent should not touch any other parts of the servomotor

when wiping the shaft.

1)

Storage

temperature When

the servomotor is not in use, it should be kept in a place with an

environment temperature between −20°C and

+60°C.

2)

Installation

site Servomotor

should be installed indoors, and the environment should meet

following conditions:

-

Free

from corrosive, inflammable or explosive gases

-

Well

ventilated and free from dust and moisture

-

Ambient

temperature is between 0°C and 40°C

-

Relative

humidity is between 26% and 80% RH (non-condensing)

-

Maintenance

and cleaning can be performed easily

3)

Installation

concentricity

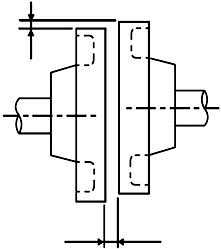

Use

elastic shaft connectors as many as possible for mechanical

connections. The axis centers of servo motor and mechanical load

should be kept in thesame line. If a shaft connector is used when

installing servo motor, it has to meet the requirement of

concentricity tolerance as shown in the illustration below. Measure

this at four quartering positions of a cycle. The difference between

the maximum and minimum measured value must be less than 0.03mm.

(Rotate together with shaft connectors)

Note:

If

the concentricity tolerance is too big, mechanical vibration will

occur, resulting in damage to the bearings of servo motor

Never

strike at the axis direction when installing shaft connectors, this

could damage easily the encoder of servo motor.

4)

Installation direction The servomotors

can be installed,

horizontally, vertically or in any direction.

5)

Handling oil and water If the servomotor

is installed at a

location subject to water, oil, or condensation, the motors require

special treatment to meet protection requirements. If the motors are

required to meet the protection requirement before leaving the

factory, it’s necessary to designate the exact motor models

with oil seal. Shaft through section means the gap as shown in the

following picture:

6)

Cable

tension When

connecting the cables, the bending radius shouldn’t be too

small, do not apply big pulling force to cables.

Please

be noted in particular that the diameter of signal cable wires is

very small, from 0.2 mm to 0.3 mm, therefore handle the cables with

adequate care and do not cause excessive cable tension while doing

wiring.