Tytuł: servo AC 750W 2.39Nm 3000rpm

Wiadomość wysłana przez: markcomp Grudnia 10, 2009, 04:37:56

(http://www.markcomp77.p9.pl/img/servo_motor_ac_750W-m.jpg)

(http://www.markcomp77.p9.pl/img/servo-motor.jpg)

(http://www.markcomp77.p9.pl/img/servo-motor01.jpg)

(http://www.markcomp77.p9.pl/img/servo-motor-wymiary-03.jpg)

-moment ciągły 2.39Nm

-moment w piku do 300% momentu ciągłego

-prędkość maksymalna do 4500rpm

-enkoder inkrementalny 2500ppr

-moc 750W

(http://www.markcomp77.p9.pl/img/servo-motor-charakterystyka-02.jpg)

A - obszar pracy w trybie ciągłym

B - obszar pracy powtarzalnej

(http://www.markcomp77.p9.pl/img/servo01.jpg)

(http://www.markcomp77.p9.pl/img/servo-wymiary02.jpg)

(http://www.markcomp77.p9.pl/img/servo-parametry03.jpg)

sterownik serva:

zasilanie: 200-230V 50/60Hz 6.3A

wyjście: 3fazy, 0-200V, 0-333Hz, 4A, 750W

przykładowe podłączenie

(http://www.markcomp77.p9.pl/img/servo-przylaczenie03.jpg)

gniazda servomotoru

(http://www.markcomp77.p9.pl/img/servo-plub-encoder.jpg)

(http://www.markcomp77.p9.pl/img/servo-plub-motor.jpg)

zdjęcia

(http://www.markcomp77.p9.pl/img/servoDrive01m.jpg)

(http://www.markcomp77.p9.pl/img/servoMotor02m.jpg)

opis wejść

(http://www.markcomp77.p9.pl/img/servodrive.jpg)

Tytuł: servo AC 750W - General Precaution

Wiadomość wysłana przez: markcomp Maja 05, 2010, 02:48:09

General Precaution

-

Power supply voltage should be AC 220V. This servo system requires a power supply of AC 220V+/-15% voltage.

-

Don’t connect the servo motor directly to local electric network. It’s prohibited to connect the servo motor directly to local electric network. Otherwise, the servo motor is very likely to get damaged. The servo motor will not rotate without support of servo drive.

-

Don’t plug in or unplug the connectors when power is ON. Internal circuit and motor encoder might be damaged if the plug in or unplug operations are performed during power ON. Always turn the power OFF first before plugging in or unplugging the connectors.

-

Wait for at least 5 minutes before doing inspection work on the servo system after turning power OFF. Please be noted that even when the power is turned off, there will still be some electric energy remained in the capacitors of the internal circuit. In order to avoid electrical shock, please make sure inspection work is started 5 minutes after Charge indicator is OFF.

-

There should be a space of at least 10mm between the servo drive and any other devices mounted in the electrical cabinet. The servo drive produces heat during working, heat dissipation should be considered in design of mounting layout. At least 10 mm space in lateral direction and 50 mm space in longitudinal direction are required from servo drive to other equipments when doing installation. Please install the servo drive in an environment which is free from condensation, vibration and shock.

-

Noise rejection treatment and grounding. The noise from signal wires causes easily the mechanical vibration and malfunctions. Please comply with the following rules strictly:

-

Route high-voltage power cables separately from low-voltage power cables.

-

Make short cable route as possible.

-

Single point grounding is required when mounting the servo motor and servo drive, and grounding resistance should be lower than 100Ω.

-

It’s prohibited to apply power input noise filter between servo drive and servo motor.

-

Withstand voltage test of servo drive should meet following conditions:

-

Input voltage: AC 1500Vrms, 1 minute

-

Interrupt/Break current: 100mA

-

Frequency: 50/60Hz

-

Forcing point: Between Terminal R, Terminal T and Terminal E.

-

Apply a fast-response leakage protector It’s required to use a fast-response leakage protector or a leakage protector for PWM inverter designated by supplier. Do not use a time delay leakage protector.

-

Avoid extreme adjustments or changes Don’t make extreme adjustments or changes to servo drive’s parameters, which will cause terrible mechanical vibration and result in unnecessary property loss.

-

Don’t run the servo motor by switching On/Off the power supply directly. Frequent power On/Off will cause fast aging to servo’s internal components, which will reduce the lifetime of servo drive. It’s required to use reference signals to control the running of servo motor.

Tytuł: servo AC 750W - Installation and dimension

Wiadomość wysłana przez: markcomp Maja 05, 2010, 04:14:24

Installation and dimension

Servo motor

Servomotor can be installed either horizontally or vertically. However, if the servomotor is installed with incorrect mechanical fittings, the servo motor’s lifetime will be greatly shortened and unexpected accidents will occur.

Please make installation according to the instructions as below:

Precaution:

There’s some antirust agent on the edge of the motor shaft to prevent it from rusting during storage. Please wipe off the agent thoroughly by using a cloth dipped with diluting agent or thinner before installing the motor.

NOTE: The diluting agent should not touch any other parts of the servomotor when wiping the shaft.

1) Storage temperature When the servomotor is not in use, it should be kept in a place with an environment temperature between −20°C and +60°C.

2) Installation site Servomotor should be installed indoors, and the environment should meet following conditions:

-

Free from corrosive, inflammable or explosive gases

-

Well ventilated and free from dust and moisture

-

Ambient temperature is between 0°C and 40°C

-

Relative humidity is between 26% and 80% RH (non-condensing)

-

Maintenance and cleaning can be performed easily

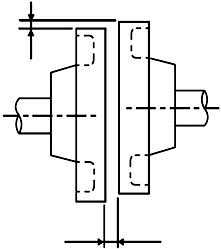

3) Installation concentricity

Use elastic shaft connectors as many as possible for mechanical connections. The axis centers of servo motor and mechanical load should be kept in thesame line. If a shaft connector is used when installing servo motor, it has to meet the requirement of concentricity tolerance as shown in the illustration below. Measure this at four quartering positions of a cycle. The difference between the maximum and minimum measured value must be less than 0.03mm. (Rotate together with shaft connectors)

Note:

If the concentricity tolerance is too big, mechanical vibration will occur, resulting in damage to the bearings of servo motor

Never strike at the axis direction when installing shaft connectors, this could damage easily the encoder of servo motor.

4) Installation direction The servomotors can be installed, horizontally, vertically or in any direction.

5) Handling oil and water If the servomotor is installed at a location subject to water, oil, or condensation, the motors require special treatment to meet protection requirements. If the motors are required to meet the protection requirement before leaving the factory, it’s necessary to designate the exact motor models with oil seal. Shaft through section means the gap as shown in the following picture:

6) Cable tension When connecting the cables, the bending radius shouldn’t be too small, do not apply big pulling force to cables.

Please be noted in particular that the diameter of signal cable wires is very small, from 0.2 mm to 0.3 mm, therefore handle the cables with adequate care and do not cause excessive cable tension while doing wiring.

Tytuł: servo AC 750W - servodrive

Wiadomość wysłana przez: markcomp Maja 05, 2010, 04:22:15

Servo drive

This series of servo drives are all base-mounted. Incorrect mounting will definitely cause problems. Always mount the servo drives according to following installation instructions.

1) Installation site The notes on installation of servo drive are as below:

- Installed inside a control cabinet A unified design for the cabinet size, configuration of servo drive, and the cooling method is required so that the ambient temperature around the servo drive is always below 55 °C.

- Installed near a heating unit Minimize the heat radiating from the heating units by taking advantage of heat dissipation measures such as natural convection current, forced-air cooling, to ensure working temperature around the servo drive is always below 55 °C.

- Installed near a vibration source A vibration isolator should be mounted underneath the base surface to prevent vibration.

- Installed at a site exposed to corrosive gases Appropriate measures should be taken to prevent corrosive from getting in. Corrosive gases does not have immediate influence on the servo drive but they will eventually cause problems on electronic components, which will definitely have influence on the running stability of servo drive.

- Other situations Do not install the servo drive in hot, humid locations or locations subject to excessive dust or powder in the air.

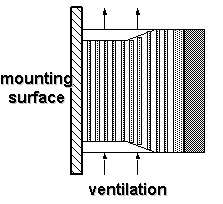

2) Installation orientation As shown in the following picture, the installation direction should be vertically mounted onto the wall, firmly fixed on the surface with two mounting holes.

A cooling fan can be mounted for forced-air cooling of the servo drive at request.

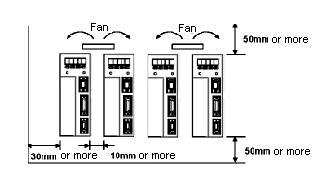

3) Installation of several servo drives

When several servo drives are required to be installed side by side inside one control cabinet, installation must be performed according to the gap requirement as shown below :

-

Installation orientation Install the servo drive vertically onto the wall so the front panel(connection board side) of servo drive faces the operator.

-

Cooling As shown in the illustration above, give sufficient space between each servo drive so that cooling by cooling fans or natural convection is good.

-

Side-by-side installation When installing servo drives side by side as shown in the illustration above, reserve at least 10 mm between two horizontal sides and at least 50 mm between two vertical sides. The temperature in the control cabinet needs to be kept evenly distributed, subject to no overheat at any part of servo drive. If necessary, install forced-air cooling fans above the servo drives to avoid excessive temperature rise.

-

Normal Working Conditions for Servo Drive

- Ambient Temperature: 0 to 55°C

- Humidity: 90% RH or less, no condensing

- Vibration: 4.9 m/s2 or less

To ensure a long term stability of the drive, it’s suggested the drive be used in a place with a temperature below 45 °C.

4) Storage condition When the servo drive is not in use, it should be kept in a place with an environment temperature between −20°C and +85°C.

Tytuł: Odp: servo AC 750W 2.39Nm 3000rpm

Wiadomość wysłana przez: markcomp Maja 06, 2010, 10:05:44

(http://www.markcomp77.p9.pl/img/s750-02.jpg)

(http://www.markcomp77.p9.pl/img/s750-03.jpg)

(http://www.markcomp77.p9.pl/img/s750-04.jpg)

(http://www.markcomp77.p9.pl/img/s750-05.jpg)

(http://www.markcomp77.p9.pl/img/s750-06.jpg)

(http://www.markcomp77.p9.pl/img/s750-07.jpg)

(http://www.markcomp77.p9.pl/img/s750-08.jpg)