sevo750W: Servo parameter adjustment methods

Servo parameter adjustment

Servo parameter

adjustment methods

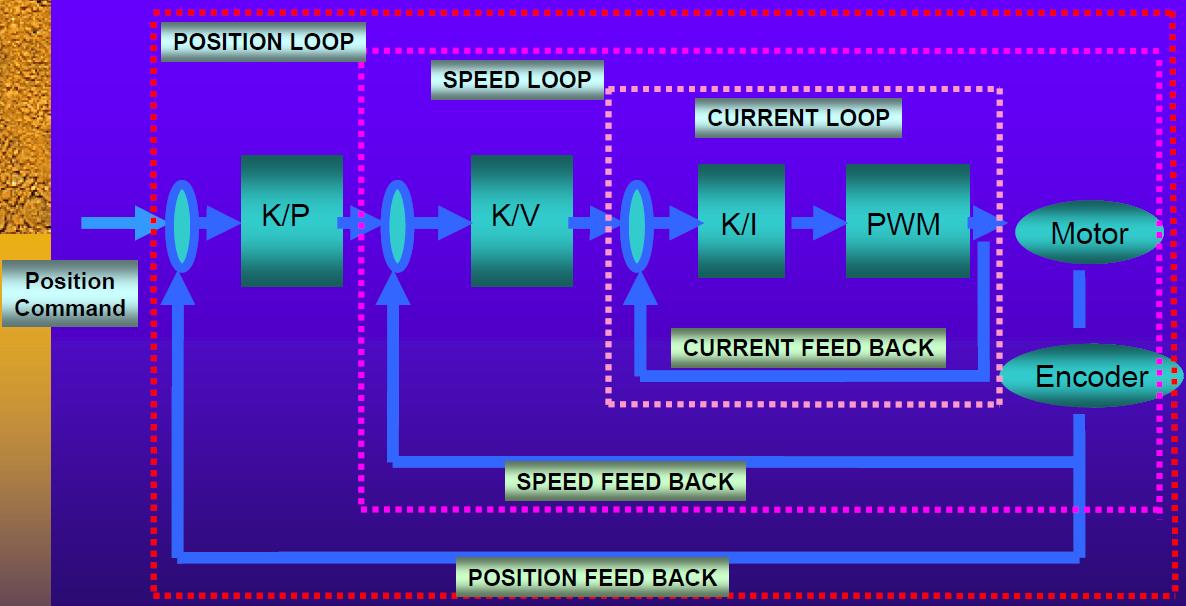

Schematic

diagram of AC servo system

Servo

driver parameter

adjustment theory foundation

Servo

driver has three feedback loops which are Position loop, speed loop

and current loop. Current loop has the highest responsiveness.

Meanwhile, speed loop must have a higher responsiveness than position

loop.

If

we do not abide by this principle, the motor will be caused to

vibration or undesired reaction. While designing the servo drive,

producer has ensured the highest responsiveness of speed loop.

Therefore, users only need to adjust the gain of position and speed

loop.

Generally

speaking, the responsiveness of position loop cannot be faster than

speed loop. Hence, it is strongly recommended to increase the gain of

speed loop first, when you want to increase the gain of position

loop. In case you only increase the gain of position loop, the motor

is likely caused to vibrate. This in turn will cause the increase of

speed reference and positioning time rather than desired decrease.

Note:

The gain of position loop cannot exceed the natural frequency of

mechanical system. Or, it will cause to vibration.

In

case there is a need of high responsiveness of the whole system, You

must not only ensure the high responsiveness of servo system

(controller, servo drive, servo motor and encoder) but high

robustness of the mechanical system as well. This way, the whole

system can achieve good robustness.

Servo drive key

parameter adjustment principle

Speed

loop gain(Pn013) Speed loop gain is mainly used to decide the

responsiveness of speed loop. Under the precondition of no vibration

of mechanical system, the bigger the value of this parameter is, the

higher the responsiveness

is.

Under

the strict precondition that setting value of the load inertia ratio

is within the permission range, speed loop gain can reach designed

value range. It, Consequently, ensures the high responsiveness of

speed loop.

Increase

the ratio of speed loop gain can enhance the robustness of servo

system. However, in real application, the ratio of speed loop gain

cannot be too large. Otherwise, it will cause the whole servo system

to vibrate.

Speed loop integration

time constant (Pn014)

Speed

loop integration can reduce the ripple of motor speed. However, it

will also reduce the responsiveness of servo drive. Speed loop

integration won’t affect speed tracing positioning reference,

however too large a speed loop integration time constant will reduce

the speed loop responsiveness. Therefore, when increase the time

constant, the drive’s reaction time will be slowed and it

needs

more time for positioning.

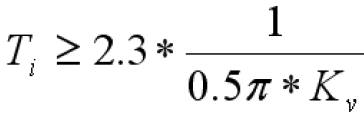

When

the load inertia is high or mechanical system is likely to vibrate,

it is strongly recommended to increase speed loop integration

time constant. Reference as follows:

Ti:

Integration time constant [s]

Kv:

speed loop gain [HZ]

Position

loop gain(Pn015) Position

loop gain is one of the fundamental index of AC servo system and has

close relation to servo motor & mechanical load. Generally

speaking, higher position loop gain will cause:

- Higher

responsiveness of motor speed

- Smaller

position tracing error

- Shorter

positioning time

However,

it requires higher relevant mechanical system robustness and natural

frequency.

Torque

reference filter time constant (Pn018) The

mechanical system may cause sharp noise due

to torque sympathetic vibration in some occasions. Increase torque

reference filter time constant can reduce or eliminate the vibration

noise.

However,

like integration time constant, it will reduce the responsiveness of

the whole system. Therefore, do not set the value of this parameter

too large.

Reference

adjustment

methods as follows:

- Set

position loop gain at a relatively lower value. Then under the

precondition that it won’t occur abnormal noise &

vibration, increase the speed loop gain to maximization step by step.

- Decrease

the speed loop gain value step by step while increase the

position loop gain. Under the precondition that no responsiveness

over-adjustment & vibration, maximize the position loop gain.

- Speed

loop integration time constant is decided by positioning time.

Please minimized this value under the precondition that mechanical

system no vibration.

- Consequently,

optimize position loop gain, speed loop gain and speed

loop integration time constant by minor adjustment step by step.